|

What is a PLC? It's a computer which runs an archaic computer language normally designed to simulate relay (or boolean) logic - the software is called 'ladder' because it's vaguely like one very large ladder with rungs - the 'rungs' being the individual lines of software. Here's an example (this is a small one):

The processors are normally very old (but quick enough since they are effectively running a form of machine code) with laughable amounts of RAM - the average small PLC comes with 4K (yes 4096 bytes, that's less than in the average digital watch) and the biggest has only about 512K. Rather less than the musical tie I got for Christmas last year. The programming software is also normally quite laughable - it's supposedly designed for the average electrician or maintenance engineer to program, but normally fails badly in this respect. 'Advanced' functions of the programming software are such exciting features as 'copying lines' and 'pasting lines'. You don't believe me do you?

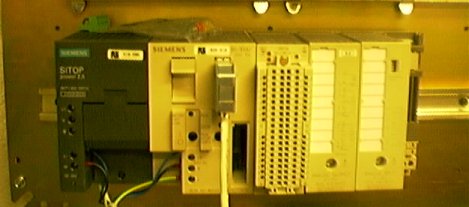

The software is totally incompatible between manufacturers, there is NO common format. In fact the software is normally not compatible even for one manufacturer. Siemens produce many PLCs, we have programmed all of the following:

Software written on a 135 cannot be placed on a 100 or even a 115. Software written on a 155 may or may not be compatible with a 135 (and so on). Please note that Siemens are probably no (or not much) worse than other manufacturers in this case. Only Mitsubishi have a conversion program to convert between different CPUs (which only achieves 90% or so accuracy anyway) So what's good about PLCs? Well the I/O is the important part - the PLC has live links to the outside world in two forms - analogue and digital. A digital signal is typically for a pump or a motor (ie on to start a motor, off to stop it). An Analogue signal is typically level (of a sump or hopper) or temperature and so on. The I/O is PLCs is robust and hard to break (except for 1 or 2 manufacturers) Siemens and Allen Bradley having particularly good I/O in this respect. The entire program is typically run 10 to 50 times per second. The concept here is that if anything goes wrong the PLC reacts almost immediately to sort it out or take emergency action. Who uses these things? They are used to produce your water, electricity, food and pretty much everything in process control industries. Back to Top

| What is SCADA? This is a bit better - it's lots of pretty graphics with a useful purpose. The graphics display parts of the plant for the operators who run them. SCADA systems produce alarms telling the operator to fix a problem. Here's a very simple example :

So who uses these things? Again they are used to in Water, Electricity, food and pretty much everything in process control industries.

| What is Ladder? It's crude simple stuff, here's an example: Segment 2 Air bad delay timer ! T 116 !I 19.1 +-----+ +---] [---+-!T!-!0! !KT 060.2 --!TV BI!- ! ! DE!- ! ! ! ! ! ! ! +-!R Q!- ! +-----+This is a time delay - when the input "I19.1" is on then the timer T116 start. When it expires the timer output Q is activated. Timers are used a lot in PLC programs - to delay starting a pump until the 'low level' probe has been active for 10 seconds say (to avoid spurious signals) or simply to time how long a pump has been running for. Another example: Segment 3 F49:Compressed Air missing ! !I 19.1 F 18.2 F 26.0 +---]/[---+---]/[---+---------+---------+---------+---------+---------+--( )-! ! ! !F 26.0 ! +---] [---+Nowadays the ladder editor is in Windows type format, but the principle is still the same...

|

Our SoftwareWe program in all PLC languages, examples being:All the programming is different, experience of one PLC is often only a little help in programming the next type.

| Communications are by far the most complex part of using PLCs. Linking two PLCs is never simple Allen Bradley Allen Bradley have the most simple communications between PLCs (Data Highway + or DH+), it's almost easy! Normally the only problem is getting the blue and clear wires the wrong way around. Siemens Siemens have the most complex systems for linking their PLCs. You stil often need to blow EPROMs and get the correct comms driver (depending on the CPU type and comms card type) and you normally need to write lots of software to get it to do the simplest thing. The communications are often limited in terms of protocol and data bits (etc) - it's not easy, definitely not for the beginner. Thinking about, Siemens Comms aren't really for anyone...except experts. Everyone Else All other "comms" problems lie somewhere in between these two. All problems are different, each PLC type has it's set of unique problems.

| You see? It's all quite simple really (OK apart from comms we admit). last change 18th June 2018 |

|---|